Hoʻohana pinepine ʻia kēia lawelawe e hana i nā hale, nā ʻāpana, a me nā ʻāpana no ka nui o nā ʻoihana, me ka automotive, aerospace, medical, a me ke kūkulu ʻana. Hiki ke hoʻohana ʻia ka wili metala a me ka hui e hana i nā huahana o kēlā me kēia nui a paʻakikī. Hoʻohana ka poʻe ʻoihana loea i kēia ʻoihana i nā mea hoʻoheheʻe kiʻekiʻe kiʻekiʻe a me nā ʻenehana e hōʻoia i kahi weld ikaika a paʻa e kū i nā kikoʻī o ka mea kūʻai. Noʻonoʻo pū lākou i ke ʻano o ka metala e hoʻohana ʻia ana a me ke kaiapuni kahi e hoʻohana ʻia ai ka huahana.

Nā Kaʻina Hana Metala Pepa:ʻoki ʻoki,Ke kulou a i ʻole ka hana ʻana, Paʻi ʻanaa i ʻoleHoʻopaʻa,wiliwili aAhahui.

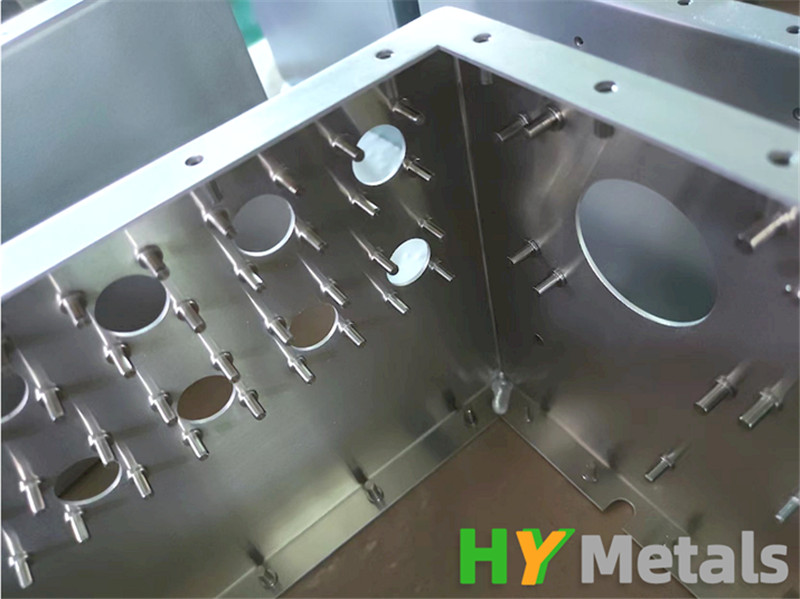

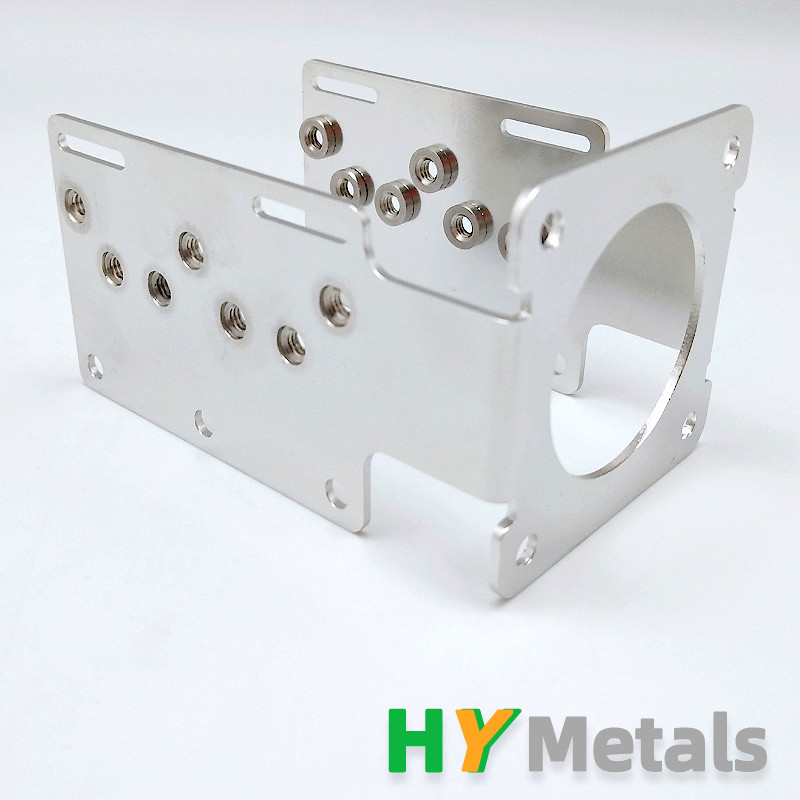

ʻO ka hui metala ke kaʻina hana ma hope o ka ʻoki ʻana a me ke kulou ʻana, i kekahi manawa ma hope o ke kaʻina hana uhi. Hoʻohui maʻamau mākou i nā ʻāpana ma ka riveting, welding, kaomi pono a me ka paʻi ʻana e wili iā lākou.

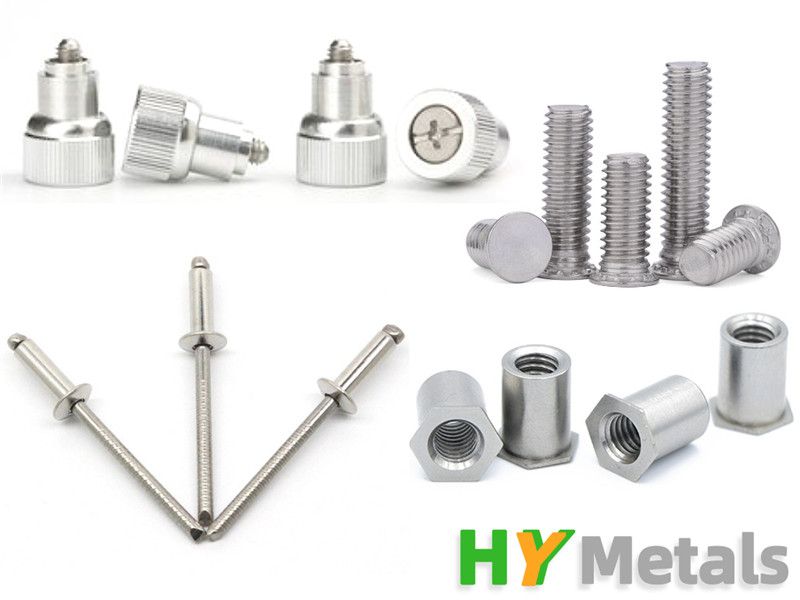

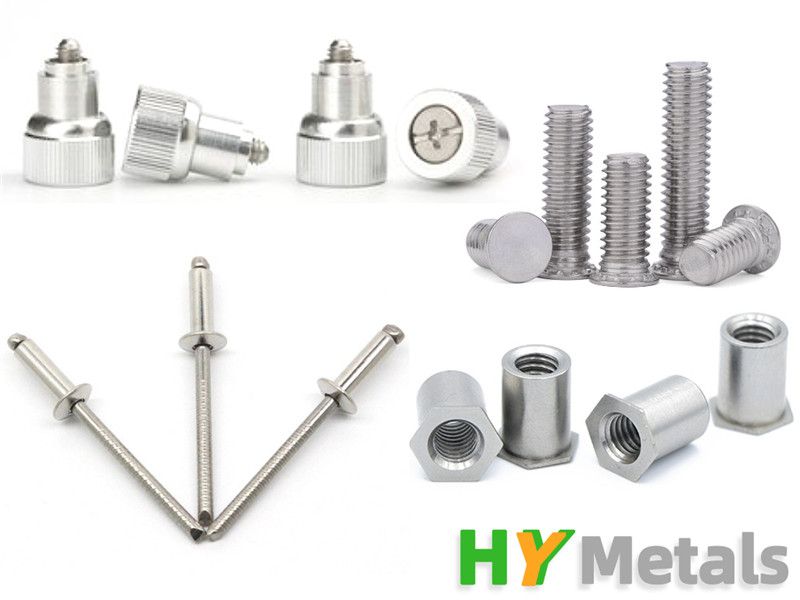

Paʻi ʻana a me ka Riveting

He kuleana koʻikoʻi nā kaula i nā hui. Aia 3 mau ala nui e kiʻi ai i nā kaula: Paʻi, riveting, hoʻokomo i nā coils.

1.Thoʻopili i nā kaula

ʻO ka paʻi ʻana he hana ia e hana ai i nā kaula i loko o nā lua no nā ʻāpana metala a i ʻole nā ʻāpana mīkini CNC me ka mīkini paʻi a me nā mea paʻahana. Hoʻohana nui ʻia ia ma kekahi mau mea mānoanoa a paʻakikī e like me ke kila a me nā ʻāpana kila.

No nā metala lahilahi a i ʻole nā mea palupalu e like me ka alumini a me nā ʻāpana plastik, ʻoi aku ka maikaʻi o ka riveting a hoʻokomo i nā coils.

2.Riveting Nuts and Standoffs

ʻO Riveting ka mea maʻalahi a maʻamau i hoʻohana ʻia i ka hoʻoili ʻana i ka pepa metala.

Hiki i ka Riveting ke hāʻawi i nā kaula lōʻihi a ʻoi aku ka ikaika ma mua o ka paʻi ʻana no ka pā metala lahilahi

He nui na Nuts, screws a me standoffs no ka riveting. Hiki iā ʻoe ke loaʻa nā lako polokalamu PEM nui a me kekahi mau lako MacMaster-Carr mai HY Metals no kāu hui.

No kekahi lako lako kūikawā ʻaʻole hiki iā mākou ke loaʻa i nā hale kūʻai kūloko, hiki iā ʻoe ke hāʻawi iā mākou no ka hui ʻana.

3. Hoʻokomo ʻana i ka mea hoʻokomo Heli-coil

No kekahi mau mea mānoanoa akā palupalu e like me nā ʻāpana mīkini palaki, hoʻokomo maʻamau mākou i nā mea hoʻokomo Heli-coil i loko o nā lua i hana ʻia e kiʻi i nā kaula no ka hui ʻana.

Kaomi iā Fit

He kūpono ka paʻi paʻi no kekahi mau pine a me ka hui shaft, a hoʻohana nui ʻia i nā ʻāpana mīkini, pono i kekahi manawa i nā papahana metala.

wiliwili

ʻO ka welding kekahi ʻano hana maʻamau i hoʻohana ʻia i ka hana ʻana i ka metala. Hiki i ka welding ke hoʻohui ikaika i kekahi mau ʻāpana.

Hiki i ka HY Metals ke hana i ka welding laser, Argon-arc welding a me Carbon dioxide arc welding.

E like me ka pae hana hoʻoheheʻe metala, ua māhele ʻia i ka wiliwili wahi, ka hoʻopiha piha ʻana, ka hoʻoheheʻe wai.

Hiki iā mākou ke hoʻokō i kāu mau koi āpau ma ka welding metala no kāu mau hui.

I kekahi manawa, e hoʻolale mākou i nā hōʻailona welding e loaʻa i kahi maʻemaʻe ma mua o ka uhi ʻana.